In a fast paced world, reliant on resourceful metals, society have an ongoing duty to reuse and recycle secondary materials such as; metals to preserve natural resources, landscapes, conserving energy whilst reducing emissions and unnecessary waste streams going to landfill.

The Waste and Recycling sector in particular are tasked with designing, manufacturing and installing innovative technology and equipment capable of effectively recovering scrap metals from various waste streams. In theory the majority of metals have the ability to be recycled into high quality ‘better than new’ metals. The UK scrap metal industry contributes significant value to UK based manufacturing as well as the export market as a major player in exporting of scrap metal.

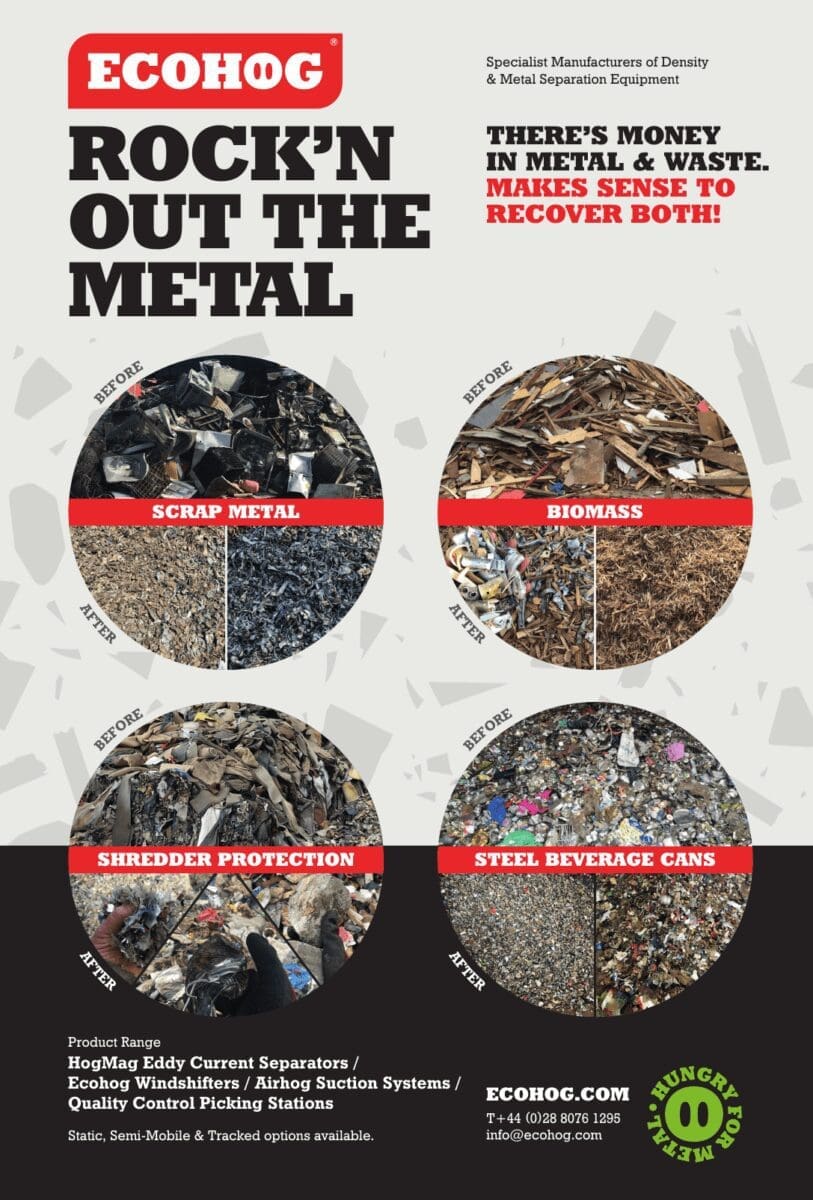

Money in Metal and Waste Recovery

As specialists in the field of Density and Metal Separation Equipment, the Ecohog Team are conversant in waste separation challenges facing processors. Working in conjunction with Waste processors, Ecohog are continually testing and analysing applications with the objective of supplying equipment proficient in achieving high quality separation. Ecohog are focused on retrieving multiple segregated waste materials with resalable value for potentially more than one commodity, ultimately diverting recyclable waste and profits from landfill. There is money in metal and in waste making perfect sense to recover both.

The Ecohog Solution

The Ecohog core product range comprises of HogMag Mobile Eddy Current Separators (ECS), EH-1500 Mobile Windshifters and Airhog Suction/Blower systems. Ecohog have developed the HogMag ECS metal separators to offer waste processors maximum Ferrous and Non-ferrous metal recovery. Each machine utilises a Vibe Pan Feeder to spread incoming material, leading to a Powerful Magnetic Drum to recover ferrous metals such as Steel and tramp iron, and then a high Gauss ECS to recover valuable non-ferrous metals such as Aluminium, Copper & Brass. The remaining material can often then be classed as “inert” and reduce landfill gate fee’s or used in waste derived fuel resources such as; RDF and SRF.

Pictured is the Tracked HogMag ECS 200o

The EH-1500 Windshifter uses a powerful air-stream, accelerator feed belt, rotating separator drum and 5-degrees of adjustability to offer waste processors the maximum quality split of Light and Heavy materials. This plays a key role in C&D/Skip Waste recycling to separate light trash materials such as; Plastic, Paper, Foil and Fluff (which can be used in waste derived fuels) from heavy more valuable materials such as; Stone, brick, metal, glass and ceramics. It also works very well in Used Beverage Can (UBC) recycling to remove light plastic, foil and packaging contamination from the heavier valuable metal cans.

Pictured is the EH1500 Tracked Windshifter

For applications that do not warrant the investment of the Windshifter unit, Ecohog offer the innovative Airhog Suction Separator range suitable the ideal compact solution for removing unwanted light trash material from various waste streams. As an example the EH-81 or HSB-81 can be used to separate pesky polystyrene balls from different waste types and also as a final clean-up stage on valuable fractions such as; scrap metal and woodchip biomass.

For the ultimate solution to recover metal from even the trickiest waste contact Ecohog today.